We received this 1920 Steinway Grand with rusted-out strings, seized action, and shattered glass embedded in the case. The piano needed a complete restoration and was in some of the worst shape we’ve ever seen.

Because of this, we’ve decided to do something we’ve never done before: take you behind the scenes and show you the step-by-step process of a complete Lindeblad rebuild.

Check out these before and after pictures and then scroll down for the behind the scenes.

Before and After Photos

Restoration Journey – A Behind-The-Scenes Look

And now for a behind-the-scenes look at what went into this remarkable restoration. To begin, former Steinway Master Craftsman and Soundboard Specialist, Galo Torres, removed the old soundboard.

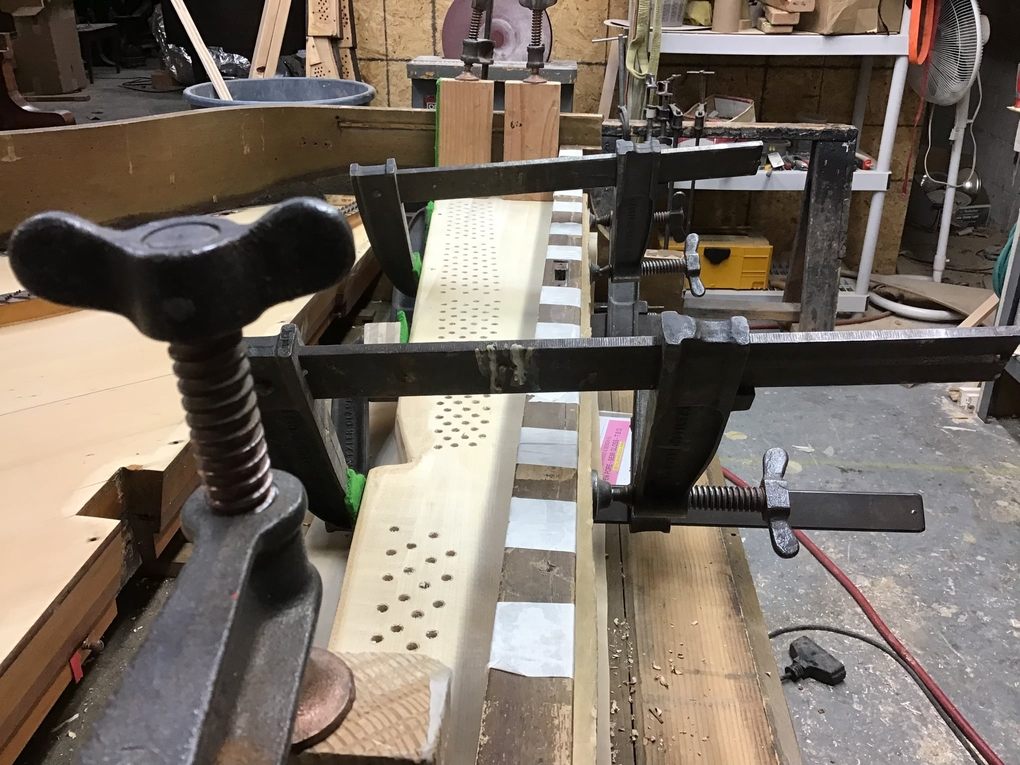

Next, the old pinblock was also removed and replaced with a new one.

The pinblock is built from five layers of hard-rock maple and is responsible for tightly securing the piano’s tuning pins at a seven-degree angle. If the pins become loose over time, the piano will no longer be able to hold a tune.

Look through these next photos to see pinblock specialist and former Steinway employee, Adams Romoleroux, craft a new pinblock for this 1920 Steinway Grand.

Former Steinway Master Craftsman, Galo Torres, then crafted a new soundboard to Steinway specifications and installed it.

Once the new soundboard was installed, the next step was to remove any pre-existing stain and finish until all that’s left was the piano’s untreated veneer. Then the cabinet was sanded to remove any other imperfections.

Did you know that the piano’s harp holds approximately 40,000 pounds of string tension?

To restore this harp to its former beauty, Lindeblad carefully, stripped, sanded and primed the harp before re-bronzing it. See the photos below to watch this transformation take place.

While the harp was getting re-bronzed, the piano’s case was busy getting refinished. Here are some of the before and after photos!

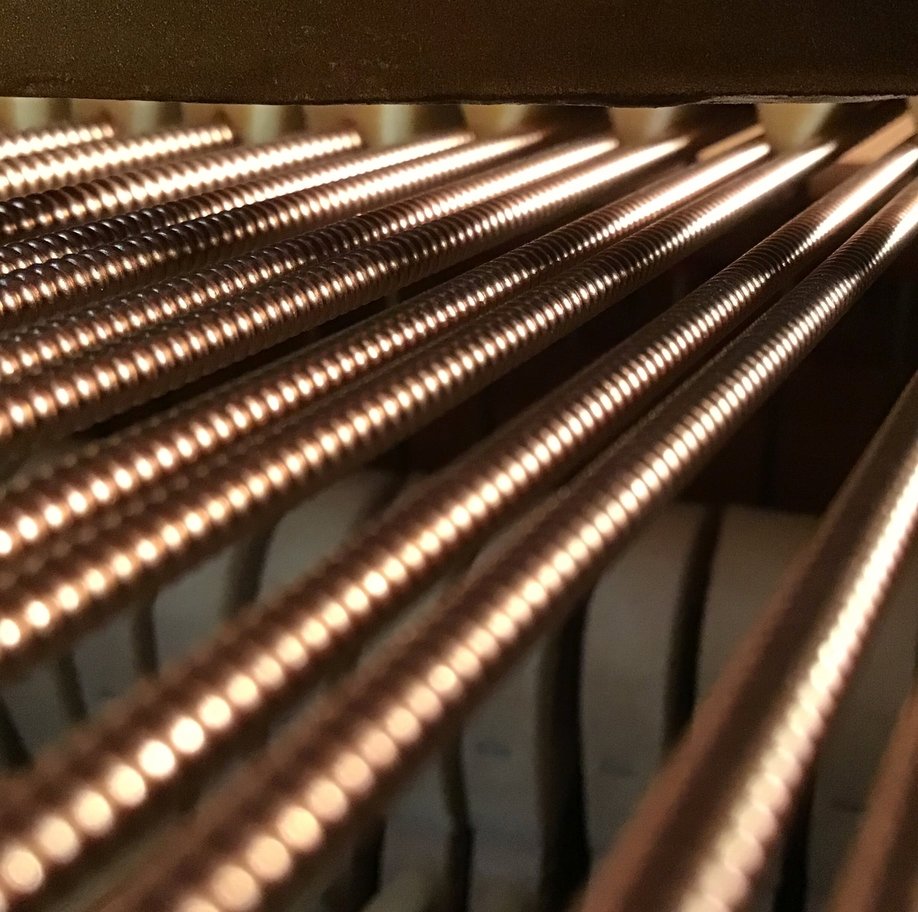

Due to the old strings being heavily rusted out from water, we had our Stringing Craftsman and Keytop Specialist, Peter Lindeblad, refit this piano with all new agraffes, tuning pins, and strings.

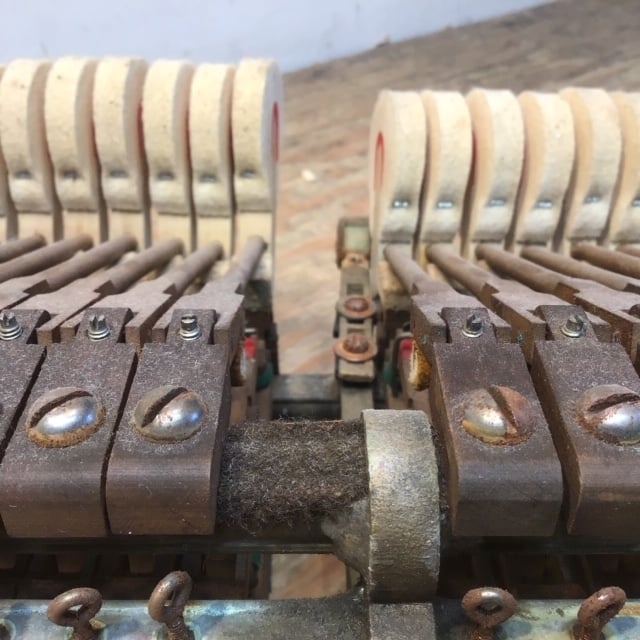

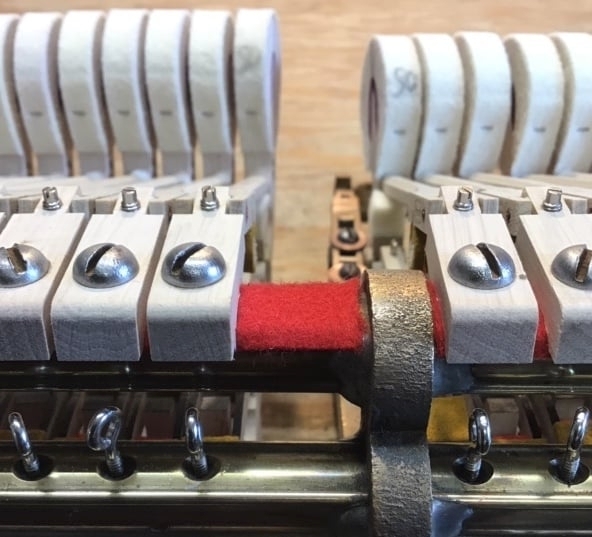

There are 12,000 parts in a Steinway grand.

Over 10,000 of these parts move and many are found in the piano's action.

Without the action working properly, the pianist will lose the ability to play with the same dynamic range and clarity that they could before. And that’s exactly what has happened with this deteriorated 1920 Steinway Grand.

To solve the issue, Lindeblad removed all the damaged, worn-out parts before completely refitting this piano with all-new parts.

The piano keys are the focal point of any piano.

To restore these worn-out keys, the keytops were completely replaced, the key body refit and weighted to spec, and all new felts were applied to the keybed.

With about 150 years of combined experience, Lindeblad’s action department then began the final steps of restoration by voicing and regulating this piano’s action.

To add the finishing touches, the piano then had its strings tuned and cabinet buffed out before the lid and other parts were assembled.

We hope you've enjoyed seeing the behind-the-scenes of a complete Lindeblad rebuild! Our experienced team of craftsmen has seen it all and work to deliver the highest quality every time.

Click here if you'd like to watch a video of this finished 1920 Steinway Grand being played.