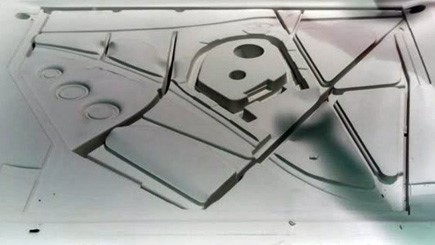

The harp of the piano is a large, cast iron plate that comprises over half of a piano’s weight. Responsible for bearing over 20,000 pounds of string tension, the harp is made from a single, continuous cast. There are two methods of casting a piano’s harp. In this blog, we’ll review the traditional process of wet sand casting versus the more contemporary process of Vacuum Shield Mold Process (a.k.a. “V-Pro”) casting.

Before we dive into which method is better and why, let’s discuss what each of these processes entails.

Defining Wet Sand Casting versus "V-Pro" Casting for Piano Harps

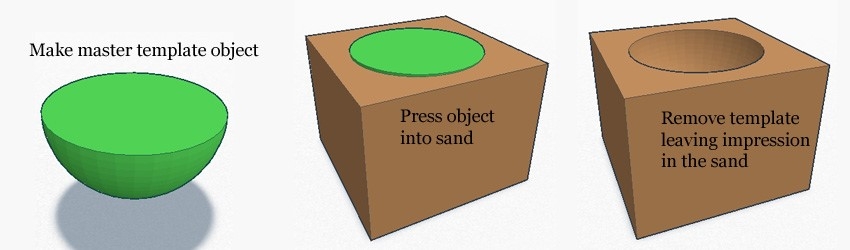

Wet sand casting is essentially pressing the carved, wooden form of a harp into damp, fine sand, and then removing it. The moisture in the sand allows it to keep the shape of the wooden form after it’s removed. Next, a precise mixture of molten iron is poured into the mold. Once cool, the cast-iron harp is removed from the sand and allowed to cure for several months, or even years, outdoors. This might seem like an odd step, but seasonal temperature changes help the grain of the metal to align and strengthen. After the harp has been sufficiently seasoned, it is sandblasted, ground, filled, and smoothed to the exact specifications of the piano it will go in.

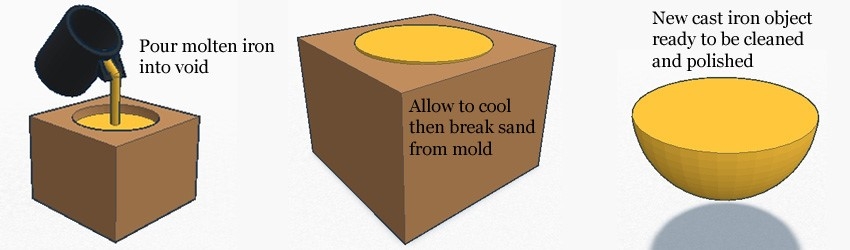

V-Pro casting is a process patented by Yamaha in the late 1970’s that is used by many mass-produced piano manufactures. In short, an exact mold of a harp is lined with a special membrane, and a vacuum sucks molten iron into the mold, resulting in a very precise finish. This process is extremely fast, doesn’t produce harps that need to be seasoned, and requires less finishing work, so it is the preferred method for manufacturers that must produce a large volume of pianos quickly. [1]

Which Piano Harp Casting Method Is Better?

One of the primary reasons we prefer wet sand casting always over V-Pro is the sound quality of a handmade piano is going to far exceed the V-pro cast, mass-produced pianos. Many professional pianists have noted that instruments containing harps made using the V-Pro method are more metallic sounding. Wet sand cast plates consist of a higher density metal, which absorbs vibrations from the strings, so the resulting sound is much clearer. In an effort to save money, V-Pro cast harps are usually made to be thinner than traditional wet sand cast harps, which contributes to their reputation for producing a metallic sound. A thin harp reverberates the vibrations coming off of the strings instead of absorbing them silently – this produces an echo effect. [2]

Secondly, wet sand casting is a hallmark of the small-batch piano manufacturer. Wet sand casting is indicative of pianos that are hand-made with great care and attention to detail. Wet sand casting takes a great deal of time and each resulting harp is skillfully honed to hug every individual instrument's curves. In the V-Pro process, a machine might produce a perfect harp, but the actual piano that is man-made by the factory might possess a few, almost imperceptible faults. Just a millimeter or two of deviation can result in reduced tonal quality. When both the piano cabinet and the harp are man-made, these flaws can be accounted for and remedied.

Steinway Agrees! Wet Sand Casting Is Essential!

Distinguished piano manufacturers such as Steinway and Mason & Hamlin only use the wet sand casting process when creating the harps to go in their instruments. For any pianist that values a pure sound and excellence in craftsmanship, the choice is simple – the wet sand casting method is the clear winner. It’s hard to contest the methods used by the greatest piano brands in the world, and at Lindeblad, we whole-heartedly believe that the time investment that is made in the wet sand casting process is well worth it.

If you're curious whether your piano has a wet sand cast harp or not, we can help you figure that out. The difference could mean a significant difference between its value for restoration or not. To learn more about the difference between wet sand casting and the alternative methods used by mass-producers, contact us today!

References:

[1] https://goo.gl/UtXL4k

[2] https://www.pianobuyer.com/Articles/Detail/ArticleId/120/Sales-Talk

Images:

https://pianopricepoint.com/casting-iron-piano-frames/

https://www.chuppspianos.com/services/grand-piano-parts/plate/

http://www2.parsonsmusic.com/en/yichang-precision-piano-cast-iron-plate-production-factory

https://www.pianolifesaver.com/english/blog/the_changing_piano_world